Introduction

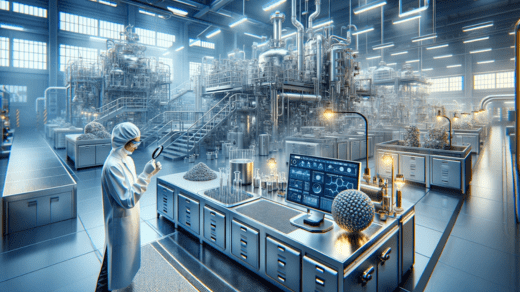

Catalysts play a crucial role in various industrial processes. It is majorly used to accelerate chemical reactions and enhance efficiency. These essential compounds often consist of precious metals and other valuable materials. This makes their recovery a significant concern for economic and environmental reasons.

However, many people do not understand what chemical catalyst recovery is. Therefore, this article will discuss its meaning and process in detail. So, stay tuned till the end.

What is Catalyst Recovery?

Catalyst recovery is the process of retrieving and reusing catalysts. These are substances that facilitate and accelerate chemical reactions without undergoing permanent changes themselves. Catalysts are often valuable and can be used repeatedly. This makes their recovery economically and environmentally beneficial. The goal is to enable the reuse of catalysts in various industrial processes while minimizing waste and promoting sustainability.

How is Catalyst Recovery Done?

Chemical Catalyst recovery is a thorough process that involves separating and reclaiming catalyst materials from the reaction mixture. It is carried out in the following steps:

1. Separation

The initial separation of catalysts involves extracting them from the reaction mixture. This step is often facilitated by centrifugation or other separation techniques to isolate the catalyst from other components.

2. Deactivation

The catalysts are deactivated after getting separated. This deactivation ensures that the components do not do any other catalytic activity.

3. Cleaning

Catalysts are cleaned using oxidation processes. It is the process of adding oxygen or removing hydrogen from a compound. This removes impurities and contaminants from catalysts that accumulate during the reaction.

4. Filtration

Filtration is a fundamental step in the recovery of catalysts. It allows for the removal of fine particles and impurities, ensuring the catalyst is purified and ready for reuse. Various filtration products come into play during this phase.

5. Reuse

The recovered catalyst is then prepared for reuse in subsequent reactions. Thus contributing to a more sustainable and economical industrial process.

Conclusion

In conclusion, chemical catalyst recovery is a crucial practice for industrial processes. The ability to retrieve and reuse catalysts not only conserves valuable materials but also promotes sustainability by minimizing waste. Through this meticulous process of recovery, industries can significantly enhance the efficiency of their operations.

Moreover, businesses contribute to a more responsible and cost-effective approach by adopting recovery techniques for catalysts. This further aligns with the global push towards environmentally conscious practices. Thus, prioritizing this process undoubtedly emerges as a crucial step towards a greener and more sustainable future in industrial chemistry.