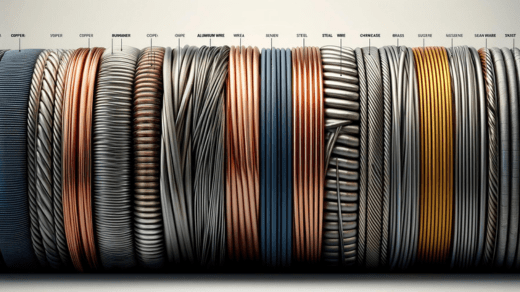

Learn how to distinguish between different metal wire types and applications in this comprehensive guide!

Are you looking to enhance your understanding of metal wire types, their distinct characteristics, and practical applications across various industries? Metal wire is a versatile material with applications ranging from construction to electronics. Identifying the right metal wire type is crucial for ensuring optimal performance in specific applications. In this comprehensive guide, we will delve into the intricate world of metal wire types, exploring common varieties, key characteristics, identification tips, practical applications, and how to distinguish between different types effectively.

Understanding the Importance of Identifying Metal Wire Types

Identifying different types of metal wire is crucial for ensuring the right material is used for a particular purpose. Different types of metal wire possess unique properties that make them suitable for specific applications. For instance, stainless steel wire offers excellent corrosion resistance, making it ideal for outdoor use or in environments with high moisture levels. On the other hand, copper wire is known for its high electrical conductivity, making it a preferred choice in electrical wiring.

Common Metal Wire Types Used in Manufacturing

Stainless Steel Wire

Stainless steel wire is a popular choice due to its corrosion resistance, durability, and aesthetic appeal. It is commonly used in applications where exposure to moisture or corrosive elements is a concern, such as marine environments, outdoor structures, and kitchen appliances.

Copper Wire

Copper wire is prized for its high electrical conductivity, making it an essential material in electrical and electronics industries. It is used in power transmission, telecommunications, and electronic circuitry due to its superior conductivity properties.

Aluminum Wire

Aluminum wire is lightweight and offers good conductivity, making it a cost-effective alternative to copper in various applications. It is commonly used in power distribution, overhead transmission lines, and as a conductor in electrical wiring systems.

Galvanized Steel Wire

Galvanized steel wire is coated with a layer of zinc to enhance its corrosion resistance. It is widely used in fencing, construction, and industrial applications where durability and strength are paramount.

Key Characteristics of Different Metal Wire Types

Conductivity

The electrical conductivity of a metal wire is a critical factor in applications where the transmission of electrical signals is essential. Copper is renowned for its high conductivity, while aluminum offers a more cost-effective option with slightly lower conductivity.

Corrosion Resistance

The ability of a metal wire to resist corrosion is vital in outdoor or harsh environments. Stainless steel and galvanized steel wires are preferred for their excellent corrosion resistance properties, ensuring longevity and durability in challenging conditions.

Strength

The strength of a metal wire determines its load-bearing capacity and suitability for structural applications. Steel wires, including stainless steel and galvanized steel, are known for their high tensile strength, making them suitable for demanding applications where durability is paramount.

Tips and Tricks for Identifying Metal Wire Types

Visual Inspection

Examine the color, texture, and surface finish of the wire to narrow down the potential material. Stainless steel wire typically has a shiny, silver appearance, while copper wire has a distinctive reddish-brown hue.

Conductivity Testing

Use a multimeter to test the electrical conductivity of the wire. Copper wire will exhibit high conductivity, while other metals may show lower readings.

Magnetic Properties

Some metal wires, such as steel, exhibit magnetic properties due to their iron content. Use a magnet to determine if the wire is ferromagnetic, which can help identify steel or iron-based materials.

Practical Applications of Various Metal Wire Types

Stainless Steel Wire

Stainless steel wire is commonly used in architectural applications, such as balustrades, handrails, and decorative elements. Its corrosion resistance and aesthetic appeal make it a popular choice for both indoor and outdoor projects.

Copper Wire

Copper wire is indispensable in electrical wiring systems, telecommunications infrastructure, and electronics manufacturing. Its high conductivity and reliability make it the preferred choice for transmitting electrical signals efficiently.

Aluminum Wire

Aluminum wire is widely used in power transmission lines, automotive components, and heat exchangers due to its lightweight nature and good conductivity. It is a cost-effective alternative to copper in various applications.

Galvanized Steel Wire

Galvanized steel wire is extensively used in fencing, wire mesh, construction reinforcement, and industrial applications where corrosion resistance and strength are paramount. Its zinc coating provides an additional layer of protection against rust and corrosion.

Mastering the Art of Distinguishing Between Metal Wire Varieties

Distinguishing between different types of metal wire requires a keen eye for detail and an understanding of key characteristics. By considering factors such as conductivity, corrosion resistance, and strength, you can effectively identify the most suitable material for a specific application. Remember to leverage visual inspections, conductivity testing, and magnetic properties to accurately determine the type of metal wire you are working with.

In conclusion, mastering the art of identifying different metal wire types is essential for selecting the right material for diverse applications. Whether you are working on a construction project, designing electrical circuits, or manufacturing products, having a thorough understanding of common metal wire types, their key characteristics, and practical applications will empower you to make informed decisions and achieve optimal results.Metal Wire Type Conductivity Corrosion Resistance Strength Stainless Steel Moderate to High Excellent High Copper High Low Moderate Aluminum Moderate Good Moderate Galvanized Steel Moderate Excellent High Titanium Low Excellent High Nichrome Low Moderate Moderate Tungsten Low Excellent Very High Brass Moderate Low to Moderate Low to Moderate